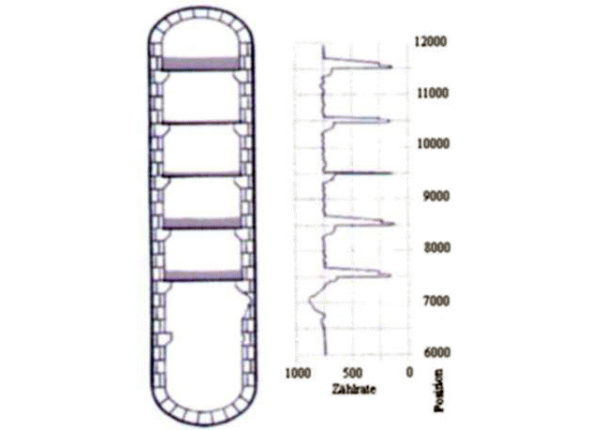

Radiometic density – / wall thickness profile measurement (Examination of the process behavior in columns)

1. task

- Implementation of non-destructive testing

- Test carried out during operation

- Process and state characterization of the column

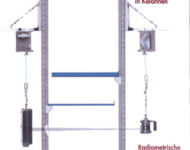

2. Testing

- Radiometric measurement of the attenuation of gamma rays passing through the column cross-section

- Spotlight: Cesium 137

- detector: scintillation

- Adjustment of the relative vertical position of emitter and detector

- Drive units flexibly mountable

- synchronous movement radiator / detector

- Continuous or step control

3. assessment

- Pulse rate at the detector and the corresponding vertical position provide a pulse-/path diagraph

- pulse rates depending on density, thickness and mass attenuation coefficient

- Location constructive fixtures directly derivable

- variations in thickness (eg material) can be detected by pulse rate differences

- Perform the specific densities of the possible outcomes to distinguishable pulse rate-/elevation

4. advantages

- Testing requires no downtime.

- process parameters (pressure, temperature, composition) do not affect the test performance.

- The manipulation device and the computer-based control and evaluation density-/thickness measurement guarantee reproducible.

- The evaluation software allows direct comparison of density-/thickness measurement at different process conditions.

- The activity of the gamma emitters require radiation protection other special measures, a failure of other radiometric measurement systems in the plant is usually excluded.